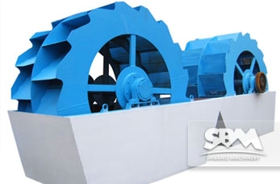

XSD Sand Washer

XSD Sand Washer is a necessary equipment in sand making plant, which is used to remove the dust in sand and improve the quality of sand. SBM's XSD Sand Washer adopts foreign outstanding technology of the same kind of products. And our sand washing machine have reached international advanced level and won customers accreditation.

+86-21-58386189

+86-21-58386189  +86-21-58386211

+86-21-58386211

-

Simple structure and low failure rate

The structure of the sand washer is simple and reasonable, avoiding the bearing causes damage by flooding, sand and pollutants.

-

Multiple functions and high degree of clean effect

The device combines washing, dehydration and grading three functions. And it can completely clean impurity by strong water flows.

-

Large capacity

The capacity up to 180tph, basically meets the customers' sand washing requirement.

-

Great clean effects

Medium-fine sand and powder' loss is very small. The fineness grade of washed construction sand can reach required standard.

The electric motor runs slowly with the impellor after decelerated by the belt, decelerator and gears wheel. The sand and stone flow into washing launder from feeding launder, rolls with the impellor, and grinds each other. The impurity covering the sand is washing away. At the same time, add more water, the strong water flow will take away waste and some low-weight wastes from washing launder. Through the above process, the washing function is finished. The clean sand and stone is lift up by vane. When it goes up slowly, the water begins to drop through the mesh and fall back in the washing launder. On one hand, water is removed from the sand and stone; On the other hand, the water can be fully used. Finally, the sand and stone goes to the out launder from the rotary impellor to finish the washing task. Characteristics of Sand Washing Machine: reasonable structure, large capacity, low consumption, little loss of the sand during the washing process, low failure rate.

| Model | Impeller (mm) | Max Feeding (mm) | Capacity (t/h) | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

| XSD2610 | Φ2600×1000 | ≤10 | 20-60 | 1.178 | 8-7.5 | Y160L-8/7.5 | 3255×1982×2690 |

| XSD3016 | Φ3000×1600 | ≤10 | 70-120 | 1.179 | 8-15 | Y200L-8/15 | 3845×3000×3080 |

This product is a kind of filtering equipment for the mining, metallurgy, chemical industry, in particular a cylinder washing machine. This product the drum washing machine comprises a cylinder block device, transmission device, roller, roller devices, sprinklers and tanks, of which device is provided with a four-cylinder of the cylinder: for junior drum washer, primary screening tube in turn, the second washing drum and quadratic sieve tube. At the primary and secondary drum washer bottom install gear roller and roller device; and between primary and primary screening drum washer tube, the second washing drum and are installed between the quadratic sieve tube obstruction. Cylinder washer described in this product can achieve the objective of obtaining the slime, filter effects, and save energy.

Get Price And Support

Respond within 24 hours !

Simply complete the form below, click submit, you will get the price list and a SBM representative will contact you within one business day. Please also feel free to contact us by email or phone. ( * Denotes a required field).