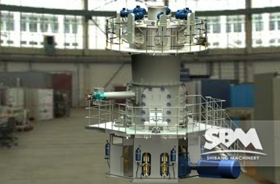

LUM Ultrafine Vertical Roller Mill

LUM Series Ultrafine Vertical Roller Mill adopts SBM abundant experience in producing vertical grinding mill and the latest technology from Taiwan & Germany. It sets grinding, drying, classifying and transportation as a whole and has been become the Mainstream equipment in ultrafine grinding industry.

+86-21-58386189

+86-21-58386189  +86-21-58386211

+86-21-58386211

- LUM is of little dust and noise, achieving Environmental Protection Request, it is quite environmentally friendly

- Utilize advanced working principle and reduce the grinding time, as a result, the final products has little iron and the whiteness and purity are raised.

- LUM has excellent grinding-efficiency for the special design of roller shell and grinding plate curve.

- Low investment cost: LUM use PLC/DCS automatic control system, well save the cost of operators.

Material falls through the screw feeder central disc, through the host drive gear motor drive disc rotating centrifugal force, so that the material is uniformly moved to lap around the area when the material through the rollers on the disc when subjected to rolling mill rolls , bulk material is directly crushed, squeezed smaller particles forming the bed after inter-particle crushing. After being crushed material to continue to move the edge of the disc, is from the inlet into the air with selected powder machine grading, the role of separator blade, does not meet the requirements of the powder particle falling into the grinding disc again, meet the standards by powder into the air separator pulse dust collection, the collection is finished powder powder discharged. Material mixed in iron and other impurities, because of the difficulty of grinding and gravity big edge through the disc, and can not be taken away by the air flow and fall into the inferior vena mill was sent Scum scraper plate mouth, discharged outside the host.

|

Model |

LUM1125 |

LUM1232 |

LUM1436 |

|

Wheel diameter(mm) |

1100 |

1200 |

1400 |

|

Capacity (t/h) |

5~12 |

7~16 |

8~18 |

|

Fineness 400~650Mesh |

~D97 |

~D97 |

~D97 |

|

Material Size(mm) |

<10 |

< 10 |

<10 |

|

Moisture |

<3% |

<3% |

<3% |

|

Main Motor Power(KW) |

250 |

315 |

355 |

|

Roller(set) |

3 |

3 |

3 |

|

Classifier Motor Power |

15 KWx5 |

15 KWx7 |

15 KWx7 |

This products public has a grinding machine, including main frame, by said main frame frame body reset has a motor, by said main frame Shang set has rotating disc, and artifacts fixed device and clip tight spring device, by said rotating disc Shang set has a sandpaper, sandpaper Shang placed has a artifacts, by said artifacts through artifacts fixed device and clip tight spring device fixed in rotating disc Shang, the fast grinding machine of maximum features is loaded clip speed fast, due to take spring clip tight way can is good of adjustment plane tilt, and for grinding effect good, occupy space small, cost lower, Very suitable for side assembling the side grinding.

Get Price And Support

Respond within 24 hours !

Simply complete the form below, click submit, you will get the price list and a SBM representative will contact you within one business day. Please also feel free to contact us by email or phone. ( * Denotes a required field).